20L 2 Cavities Full Automatic Oil Bottle Blowing Machine

This serious plastic bottle making machine is special for produce big volume PET bottles 3–20 liters with automatic preform loading and servo system, more power saving.It is widely used to produce the Soda bottle ,mineral water bottle, pesticide bottle ,oil bottle ,cosmetics,wide-mouth bottle etc.

PET blow moulding machine is used to produce 5gallon PET bottle that is now demanded extremely in the market. Facing great demand for 5 gallon PET bottle at market, we will certainly become the right machine for your investment. The whole procedure is automatic. It is controlled with microcomputer.

In order to achieve the purpose of automatic transporting bottles, the user should connect the conveyor belt with the blow molding machine. By transmission device, the machine can be connected to the filling machine directly and start inline filling .

- 10L-20L, Edible oil bottle

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

Technical features of 5 gallon stretch blow molding machine

1. Blowing system: create the high-pressure integration valve group, the single cavity productive capacity is increased by 60%.

2. Concentrated heating system: patent light box provides an even temperature, lamp distance 101mm rather than 240mm from othersand save power by more than 50%.

3. Stretching system: use linear sliding track framework instead of liner bearing, which offers an outstanding improvement ofstability.

4. Main transmission system: adopt patent double strand roller chains technology, to assure the demands of stability

and high speed.

5. Hydraulic mould clamping system replace the traditional pneumatic clamping system ,booster pressure from one sides with 2 plateforming to assure the high clamping stability at a pass rage of 99.8%.

| TYPE | ITEM | SH-15L-2 | SH-20L-2 |

| Product paramerers | Max. volume | 15L | 20L |

| NO. of cavity | 2Cavites | 2Cavites | |

| Production capacity | 1300-1600pcs/hr | 1200-1500pcs/hr | |

| Max. neck size | 45-80mm | 45-80mm | |

| Max. diameter | 260mm | 260mm | |

| Max. height | 480mm | 480mm | |

| Power specifications | NO. of lamp | 60pcs | 60pcs |

| Max. heating power | 100kw | 100kw |

|

| Total machine Power | 100kw | 100kw | |

| Actual power consumption | 22kw | 22kw | |

| Air pressure specifications | Working pressure | 0.7-0.9mpa | 0.7-0.9mpa |

| Low pressure gas consumption | 2600ltr/min | 2600ltr/min | |

| Blow bottle pressure | 25-35kg/c㎡ | 25-35kg/c㎡ | |

| High pressure gas consumption | 4500-5000ltr/min | 4500-5000ltr/min | |

| Chiller specifications | Working pressure | 5-6kc/c㎡ | 5-6kc/c㎡ |

| Temperature range | 10℃ | 10℃ | |

| Consumption | 6600kcal/hr | 6600kcal/hr | |

| Chilled water flow rate | 45ltr/min | 45ltr/min | |

| Appearance specifications | Machine size | 5.6*2.1*2.1m | 5.6*2.1*2.1m |

| Machine weight | 5.5T | 5.5T |

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

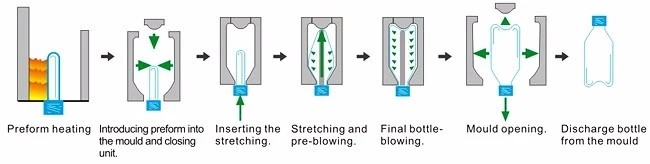

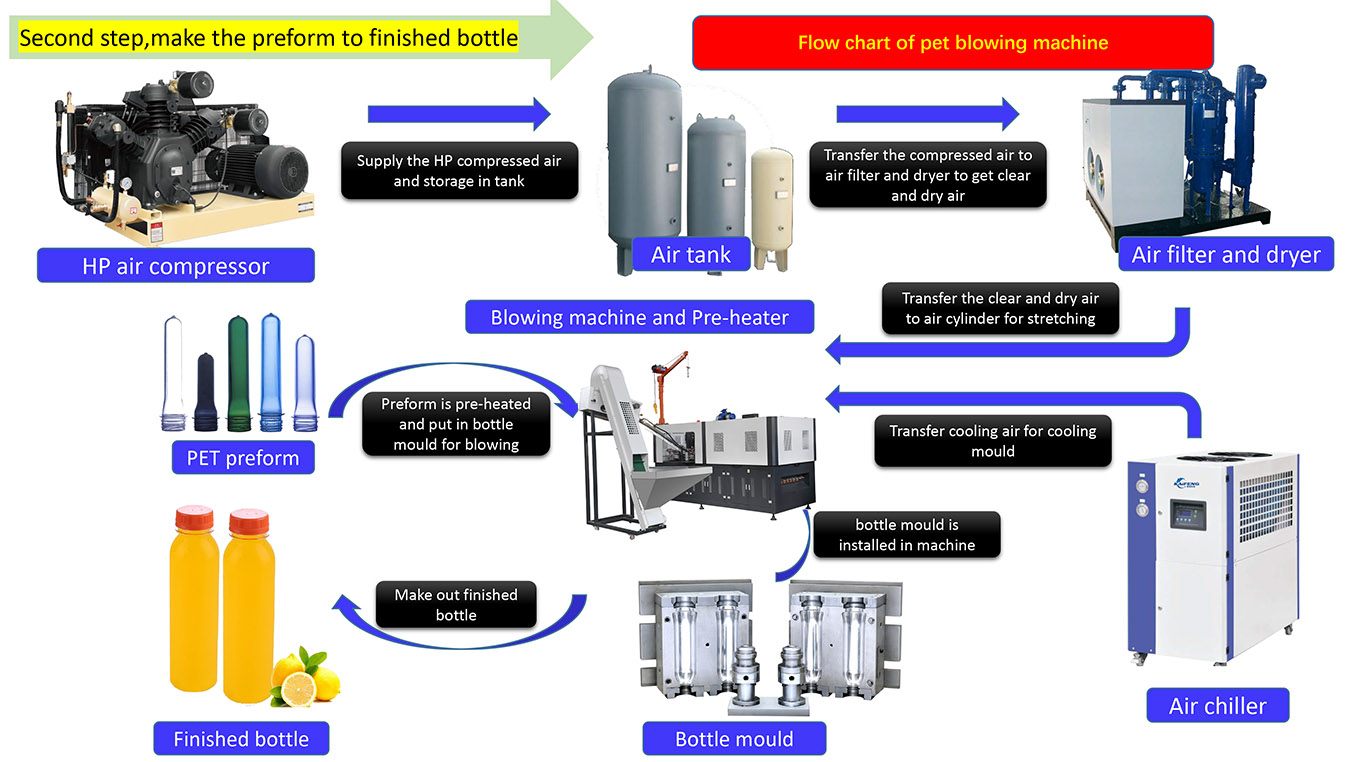

4.Working Process