600 6 Cavities Full Automatic Bottle Blowing Machine

Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

Small performs distance heating system

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

6 Cavity Full Automatic Blow Moulding Machine, with production capacity at 6,000~7,000 bottles per hour, is suitable for large water production line. The PLC micro-computer controller and human machine interface create simple operation. Independent operation station, far from heating area, is more flexible, safe to arrange operating positions.

- 550-750ml, 330-550ml, mineral water bottle, Cosmetic bottles, Jar Wide mouth

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

We are a bottle blowing machine manufacturer. We are committed to offering customized solutions for the market and customers, whether individual products or complete sets of equipment. Although the market, application, and customers are different, we have a unique concept to guide the success of customers.

We will respond patiently and carefully to any consultation and feedback from customers.

For any inquiry from customers, we will give you a professional and reasonable quotation.

For any new products of our customers, we will communicate with our customers very professionally, listen to the opinions of our customers and give useful suggestions to ensure the quality of our products.

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

| TYPE | ITEM | SH-600-6 |

| Product parameters | NO.of cavity | 6cavities |

| Production capacity | 6000-6500pcs/hr | |

| Max.volume | 0.6L | |

| Max.neck size | 28-30mm | |

| Max.diameter | 65mm | |

| Max.height | 260mm | |

| Power specifications | NO.of lamp | 56pcs |

| Max.heating power | 34kw | |

| Total machine power | 48kw | |

| Actual power consumption | 24kw | |

| Air pressure specifications | Working pressure | 7-8kg/cm2 |

| Low pressure gas consumption | 1600Ltr/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Hig pressure gas consumption | 2000-2200Ltr/min | |

| Cooling water specifications | Chiller pressure | 5-6kg/cm2 |

| Temperature range | 10.c | |

| Consumption | 8000kcal/hr | |

| Chilled water flow rate | 88Ltr/min | |

| Appearance specifications | Machine size | 5.0x2.1x2.1m |

| Machine weight | 5.0T |

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

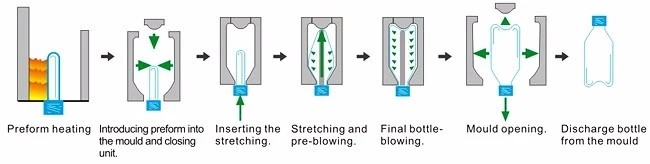

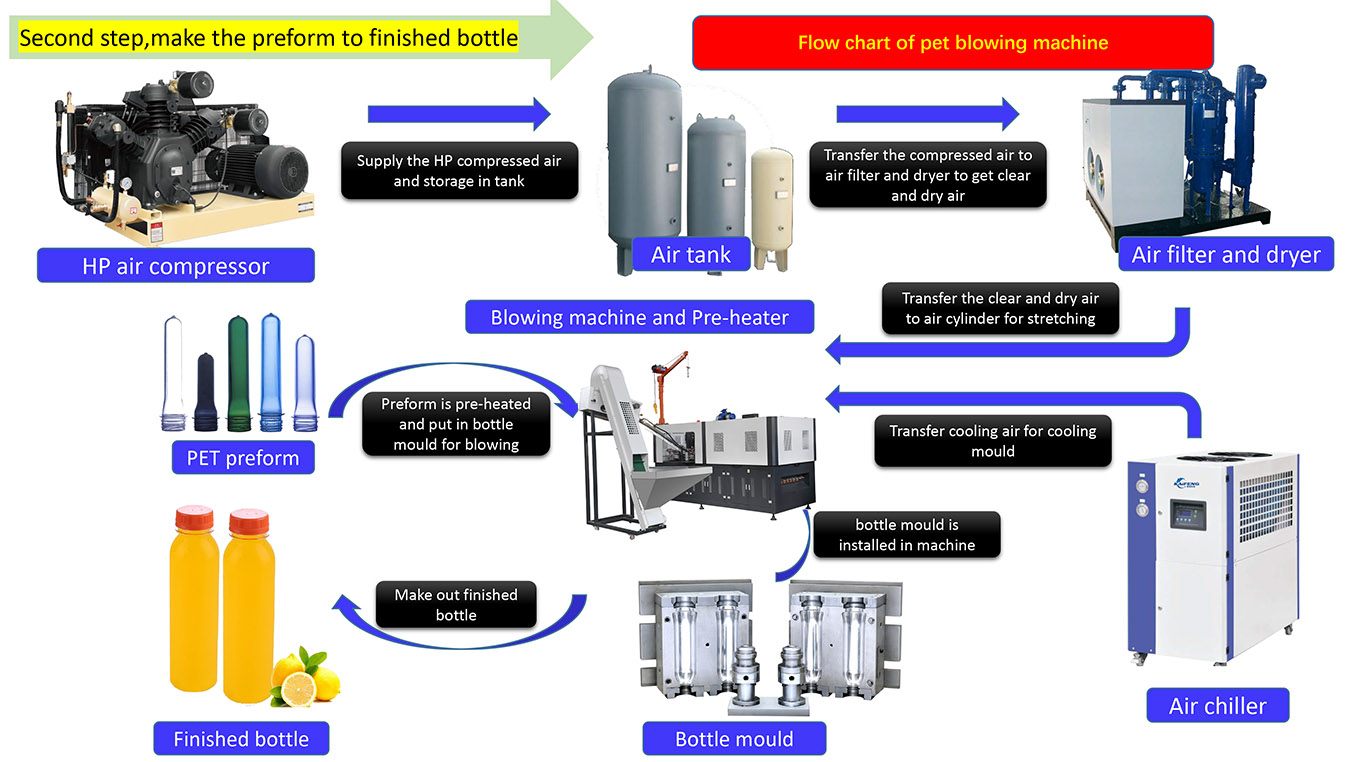

4.Working Process