Plastic Bottle Blow Molding Machine Automatic 5L Oil Bottles Bottle PET Stretch Blow Molding Machine 10L blow molding machine

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for 5l Plastic Bottle Blow Molding Machine, Fully Automatic Pet Blowing Machine, Double Stations Blow Molding Machine Price, Tank Machine,Disinfectant Bottle Making Machine. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together. The product will supply to all over the world, such as Europe, America, Australia,Eindhoven, Oman,Florida, Moscow.To work with an excellent products manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

- 1000-2000ml, 10L-20L, 3L-5.5L

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

| TYPE | ITEM | SH-5L-2 |

| Product paramerers | Max. volume | 5L |

| NO. of cavity | 2Cavites | |

| Production capacity | 1500-2000pcs/hr | |

| Max. neck size | 45-80mm | |

| Max. diameter | 190mm | |

| Max. height | 360mm | |

| Power specifications | NO. of lamp | 60pcs |

| Max. heating power | 100kw | |

| Total machine Power | 100kw | |

| Actual power consumption | 22kw | |

| Air pressure specifications | Working pressure | 0.7-0.9mpa |

| Low pressure gas consumption | 2600ltr/min | |

| Blow bottle pressure | 25-35kg/ | |

| High pressure gas consumption | 4500-5000ltr/min | |

| Chiller specifications | Working pressure | 5-6kc/ |

| Temperature range | 10℃ | |

| Consumption | 6600kcal/hr | |

| Chilled water flow rate | 45ltr/min | |

| Appearance specifications | Machine size | 5.6*2.1*2.1m |

| Machine weight | 5.5T |

series linear bottle blowing machine features:

series linear bottle blowing machine features:

1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control, simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability. 6. less than 0.2% scrap rate for finished bottle .

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

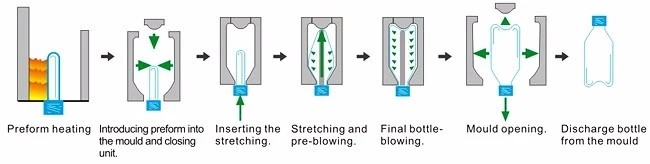

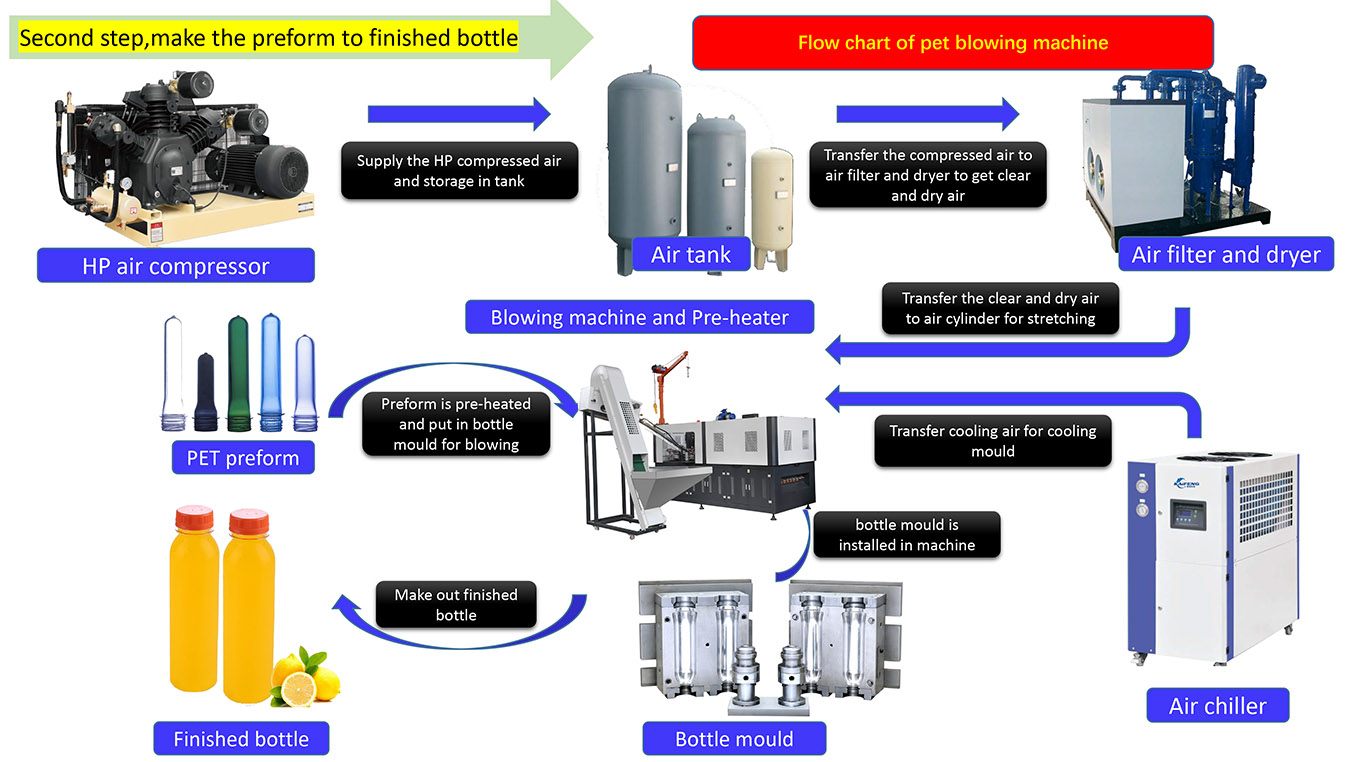

4.Working Process