20L Automatic Preform Stretch Blow Molding Plastic Water Oil Beverage Food Jar Moulding PET Bottle Blowing Making Machine

It is widely used to produce PET water bottles ranging from 6L to 20L (2 to 5 gallon). We can provide performs and various blow molds for 3gallon and 5gallon bottles to meet customer's requirements.

Product Features

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

- 1000-2000ml, 10L-20L, 3L-5.5L

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

Characteristics of automatic blow molding machine:

1.

Avoid the danger of semi-automatic manual bottle extraction, reduce the

loss caused by the accident, and improve the production efficiency.

2.

Labor saving: the machine can be operated by a single person or

multiple machines at the same time, saving 3 to 4 times the labor force.

3.

Stable performance: It adopts imported touch screen man-machine

interface computer, which has fast performance and strong stability. The

structure is simple, the oven is integrated with the slide way in the

main body, and the maintenance is convenient.

4.

Infrared lamp tube is used for heating and heating uniformly, and a

reasonable ventilation and cooling system can ensure the preform heating

and the cooling of the container mouth are stable. The PLC has

independent temperature control in sections, the design of the drying

tunnel is reasonable, can be turned over, and can be adjusted up and

down. The preform heating center distance is small, and the heating

speed is fast. The preform enters the oven, the bottleneck is upward.

Due to the oven cooling and ventilation system, the bottleneck and the

shaft will not overheat the surface of the preform, even the thick

preforms and products can be cooled well, avoiding being crystallized.

In order to ensure the yield of bottle blowing, the oven is in a more

important position in measuring the performance of the machine. The

temperature control adopts automatic feedback and closed-loop adjustment

mode.

5. The detection element

is selected from Japan's Omron omron electrical appliances, and the

strong power control is selected from imported famous products with

reliable performance.

6. With automatic alarm and automatic fault detection and judgment kinetic energy.

7.

It can store a variety of different bottle blowing process parameters.

When replacing different molds and preforms, it can be directly

retrieved from the computer without readjusting the data, and the

operation is simple.

8. Use pneumatic components imported from Germany, Japan and Taiwan.

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

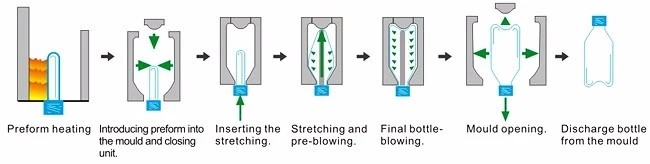

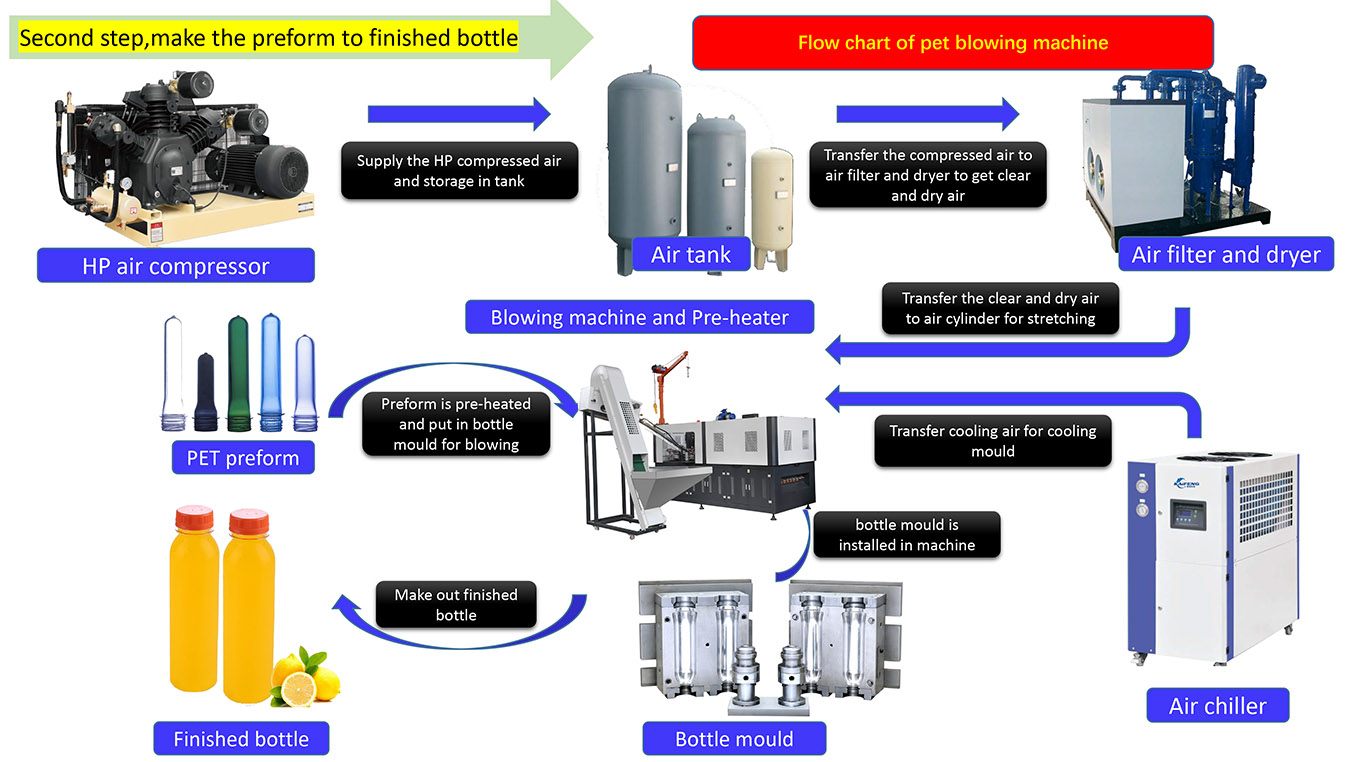

4.Working Process