Jar Wide mouth plastic bottle

Introduction to linear wide-mouth bottle blowing machine:

The linear wide-mouth bottle blowing machine is specially designed to blow wide-mouth bottles below 6L and with a mouth diameter of 38-100mm. It is suitable for blowing nuts, tea, sauces, etc. of any shape using crystalline plastics such as PET and PP as raw materials. Packaging containers for spices, dried fruits, biscuits, toys, stationery, etc.

Our Advantage

Resonable price,Good after service ,Experienced skilled workers and professional engineers ,Good quality ,excellent service ,long life mould ,On time delivery time

Choose the Meto to elevate your production capabilities and meet the growing demand for large-diameter PET bottles. Contact us today to learn more about the machine's specifications, features, and how it can transform your manufacturing processes.

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

Features of linear wide mouth bottle blowing machine:

1. It has strong versatility and is suitable for calibers of 50-180. It has a high degree of automation and is suitable for preform loading and automatic unloading of wide-mouth bottles;

2. One person can manually control two to three pieces of equipment, and can be equipped with all-electric stretching and mold clamping for high output;

3. The heat is highly penetrable and rotates through the preform itself, so that the preform receives uniform heat during the preheating process;

4. Safe, reliable and unique valve position design makes the bottle blowing process easier to control; linear bottle blowing machine

5. There is a safety locking device during every mechanical movement to protect the operator's safety;

6. The linear wide-mouth bottle blowing machine is low-cost, high-efficiency, easy to operate, easy to maintain, etc., and has advanced automatic process flow;

7. It has both automatic and manual operation modes;

8. Use different air pressures for bottle blowing and machine operation, which is energy-saving and environmentally friendly;

9. Easy to install and start, low scrap rate.

| Item |

SH-4 (PET jars) | |

| Bottle type specification | Cavity | 4 |

| Theory output | 2200-2400 bph | |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 80mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

| Power specification | Light tube quantity | 32pcs |

| Light tube power | 1KW | |

| Maximum heating power | 32KW | |

| All electric machine installation | 42KW | |

| Actual consumption | 30%-60% | |

| Air pressure specification | Work pressure | 7-9kg/c㎡ |

| Low-pressure gas consumption | 1600L/min | |

| Blow bottle pressure | 25-35kg/c㎡ | |

| Higher -pressure gas consumption | 3000Ltr/min | |

| Air pressure specification |

Work pressure | 7-9 kg/c㎡ |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 138L/min | |

| Machine specification | Machine size | 4.1x1.6x1.9 |

| Machine weight | 3.9ton | |

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

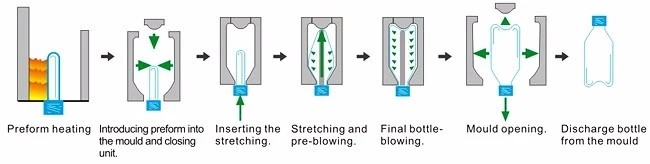

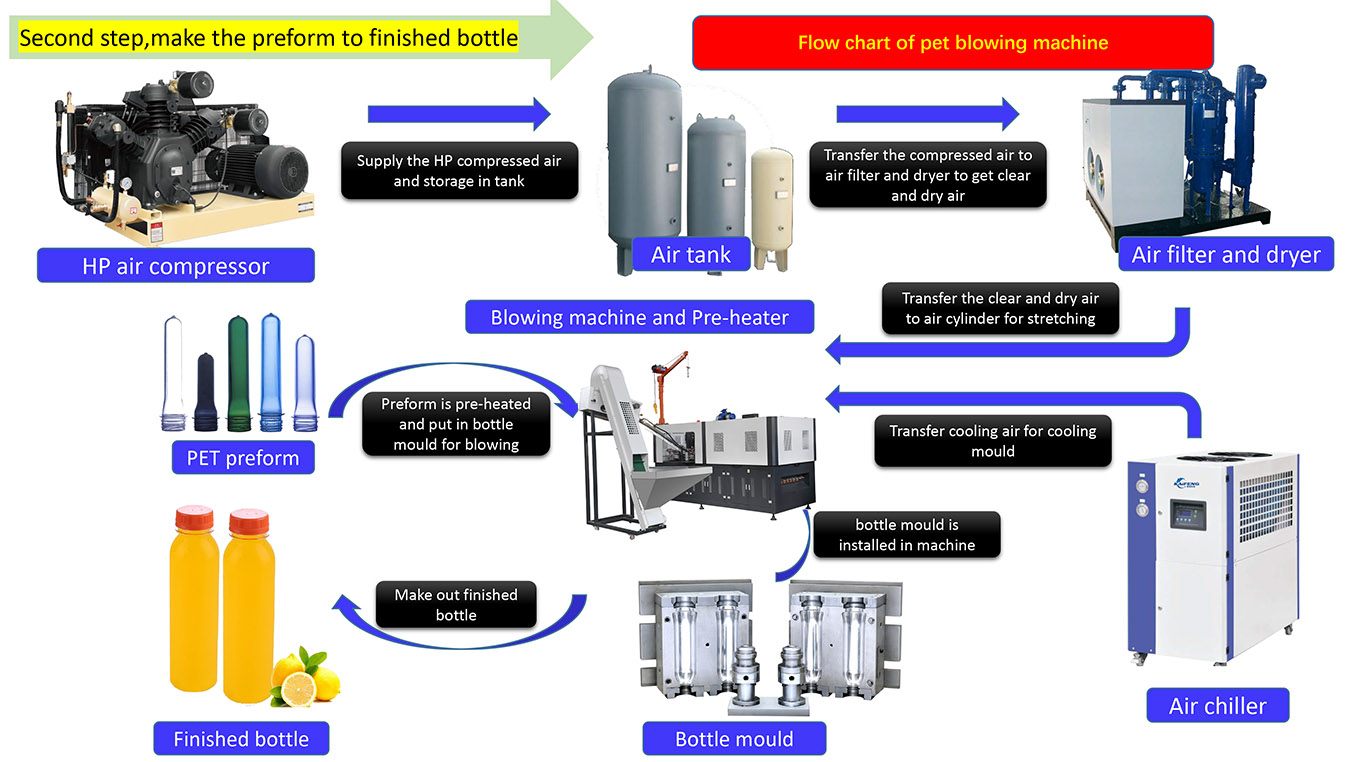

4.Working Process