Edible Oil PET Blow Molding Machine

PET edible oil bottle blowing machine, from 1 cavity to 4 cavity,blow 1L-5L PET cooking oil bottles. Bottle blowing speed, stable operation,accurate positioning, low noise, low energy consumption and other advantages.

● Max. 5-20L, 2-6 Cavities,For Big Edible Oil or Water Bottle

● Good stability, Competitive price

● Meto machinery is the first company that makes the single cavity capacity up to 700 bottles per hour(take 20L oil bottle for example)

Any bottle machine project,we can help to make professional solution for you!

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

| Unit | SH-3C3L | SH-2C5L | ||||||

| CONTAINER | Max.Container volume | L | 3 | 5 | ||||

| Max.inlet outer diameter | mm | 50 | 48 | |||||

| Max.Container diameter | mm | 180 | 180 | |||||

| Max.Container height | mm | 180 | 330 | |||||

| Number of cavities | cav | 3 | 2 | |||||

| Theoretical output | bph | 2400(*) | 1800(*) | |||||

| ELECTRICAL | Installed power | Kw | 64 | —— | ||||

| Max.heating power | Kw | 60 | 48 | |||||

| COMPRESSED AIR | Operating pressure | Mpa | 0.8 | 0.7 | ||||

| Low pressure air consuming | L/min | 2000 | 1000 | |||||

| Blowing pressure | Mpa | 3.5 | 3.5 | |||||

| High pressure air consuming | L/min | 7000(*) | 9800(*) | |||||

| CHILLER WATER | Pressure | Mpa | 0.4-0.5 | —— | ||||

| Temperature | ℃ | 10-20 | —— | |||||

| Flow rate | L/min | 100 | 40 | |||||

| MACHINE DIMENSION | Size(L×W×H) | M | 3.2×2.25×2.4 | 3.6*2*2.3 | ||||

| Weight | kg | 4500 | 6000 | |||||

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

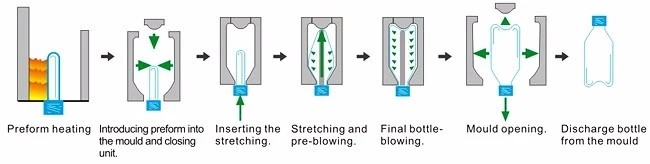

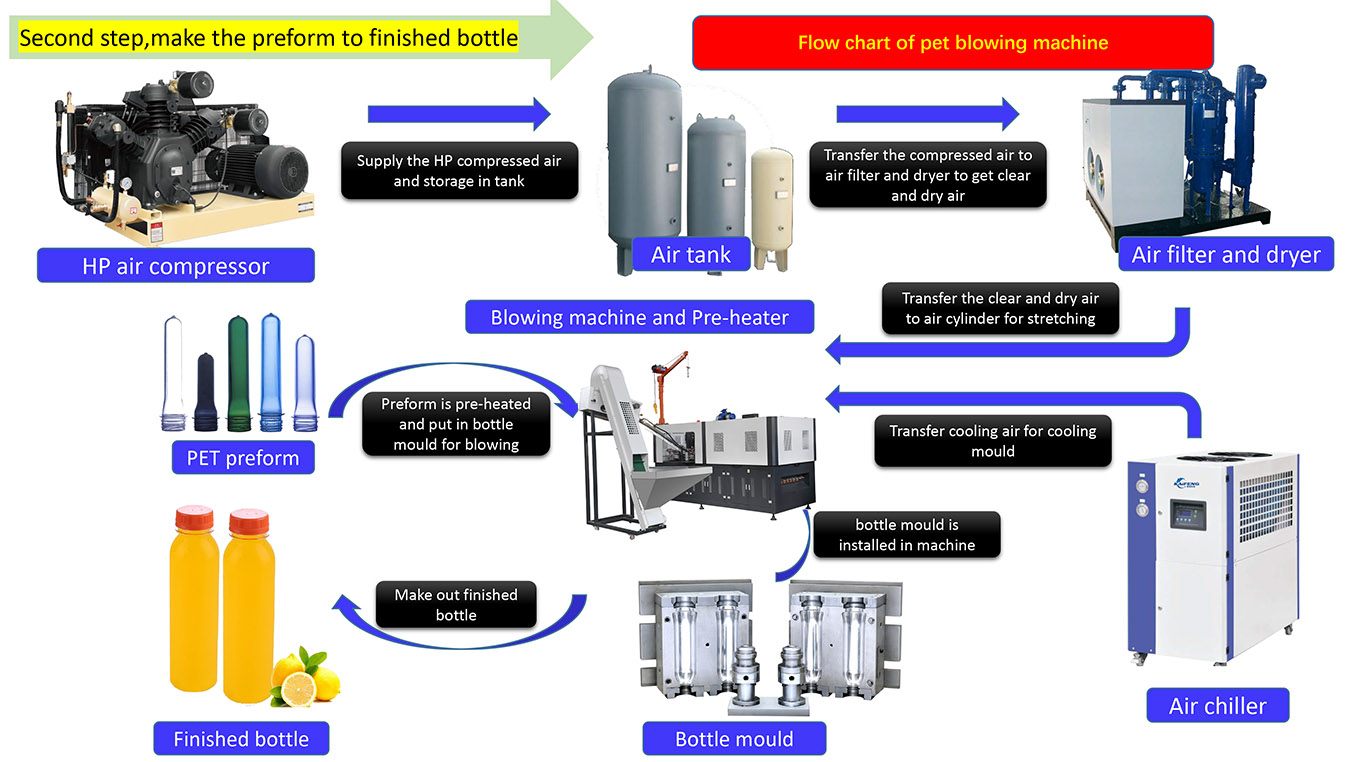

4.Working Process