2 Cavities Semi Automatic Plastic Pet Mineral Water Bottle Blowing Blower Making Maker Stretch Blow Molding Machine

The semi-automatic bottle blowing machine is controlled by a microcomputer, which can more accurately control the technical parameters involved.

Easy to operate, safe, only one person is required, and no special training is required

Suitable for blowing carbonated beverage bottles, mineral water bottles, cosmetics bottles, etc.

Machine features:

1. Processing volume 0.1-3 liter PET regular bottles, PET hot can bottle, BOPP high-temperature resistant bottles ;

2. With two cavities to product the volume 600 milliliters of bottles with output will be reach 1000 bottles per hour;

3. Advanced PLC control system, precise time control up to 0.01 seconds;

4. Special air storage device;

5. Using infrared light tubes for heating, with strong penetration, the bottle preform rotates and is heated, and the track rotates to ensure uniform heating, fast and reliable operation;

6. Different heating tubes are equipped with independent temperature control devices to ensure ideal heating effect for the preform;

7. The direction of the heating lamp tube can be adjusted according to different preform;

8. Only one person is required for operation, and no special training is required;

9. Easy installation and operation;

10. The scrap rate of finished products is less than 0.2%

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

| ITEM | SH-25 |

| Clamping force | 13T |

| Clamping stroke | 330mm |

| Max.stretching stroke | 440mm |

| Number of cavities | 0.1-3L 2cavity |

| Theoretical output | 0.5-2.5L:800-1500bph |

| Max.mould thickness | 280mm |

| Mould plate size | 490x470mm |

| Voltage standard | 380v/3PH/50Hzorspecoal order |

| Total power(full loaded) | 3-10KW 5-15KW |

| Min.air compressor | 1.2mm3/min3.0Mpa |

| Blow molding machine | 175x60x180cm |

| Pre - heater | 150x70x140cm |

| Net weight | 0.75T |

| Container volume | 0.5-2.5L |

| Neck diameter range | 28-100mm |

| Container diameter | 150mm |

| Container height | 450mm |

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

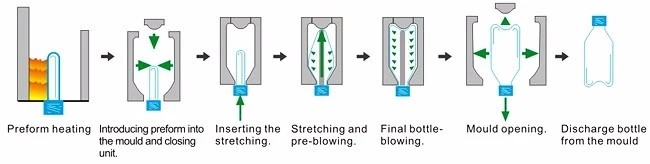

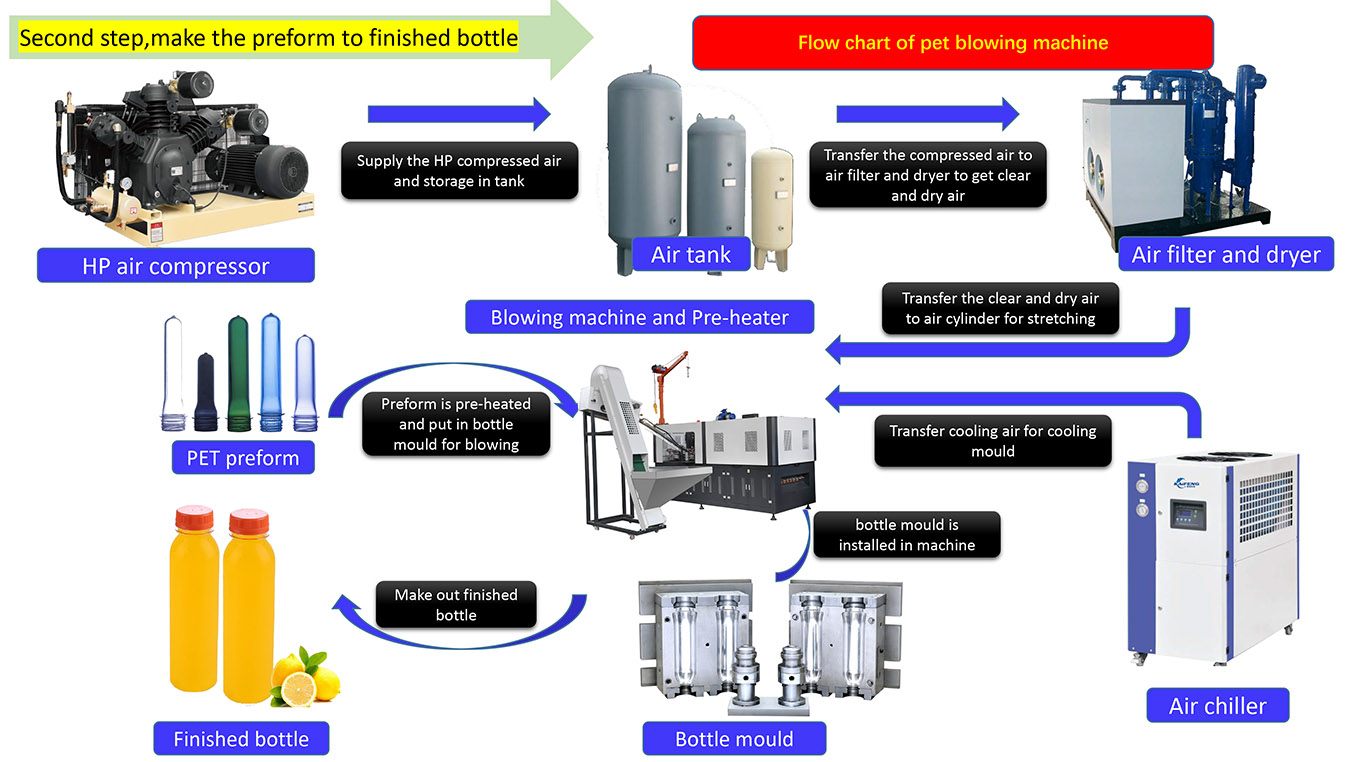

4.Working Process