5-2 Semi-automatic Bottle Blowing Machine

The two-step semi-automatic bottle blowing machine (capable of blowing PP, PET and other materials) has the following features:

1.All machines are of improved design and meet IS9001 quality system and CE standards.

2.Controlled by microcomputer, the technical parameters involved can be controlled more accurately.

3.The operation is simple and safe, only one person is needed, and no special training is required.

4.The semi-automatic bottle blowing machine can blow PET carbonated drink bottles, mineral water bottles, cosmetics bottles, hot filled bottles, pesticide bottles, oil bottles, etc.

5.The bottle blowing machine is suitable for PP milk bottle series products, with high transparency, high temperature up to 120 degrees, and can withstand secondary high temperature disinfection. It is a substitute for glass bottles.

6.The power consumption of the whole machine is small and the production capacity is high, which greatly reduces the customer's operating costs and improves the customer's production efficiency.

- 10L-20L, 3L-5.5L, Edible oil bottle

- 30-45 days easy Finish

- offers 24/7 support to ensure round-the-clock customer assistance.

Machine Introduction

The multifunctional plastic bottle blowing machine is suitable for blowing hollow plastic containers (PET, PC, AS, PE) such as carbonated drink bottles, mineral water bottles, cosmetic bottles, oil bottles, space cups, jar bottles, medicine bottles, etc.

The infrared multi-function plastic bottle preform heater is powered by three-phase four wire 380V power supply (220V power supply is also available). The machine is divided into seven layers of heating lamps, which are divided into four heating areas. The electric heating control elements are installed in the electrical box. The preheating time for starting up generally takes about 5-8 minutes. The temperature is transmitted to the temperature controller by the electric thermocouple for automatic temperature control, so that the temperature in the heating box is controlled stably, the infrared penetration is strong, the heating is uniform, fast and reliable, Ensure that the preform has an ideal heating effect. Put the preform into the bottle and heat it for a circle before production. The specific temperature shall be adjusted according to the bottle forming needs.

The unit has excellent equipment, stable product quality, wide application range, low investment, low cost, low power consumption, quick investment, convenient operation and other advantages. It is an ideal packaging machine widely used in mineral water, beverage, pesticide, chemical reagent, medicine, grease and other manufacturers.

Machine Features

The two-step semi-automatic bottle blowing machine (capable of blowing PP, PET and other materials) has the following features:

1.All machines are of improved design and meet IS9001 quality system and CE standards.

2.Controlled by microcomputer, the technical parameters involved can be controlled more accurately.

3.The operation is simple and safe, only one person is needed, and no special training is required.

4.The semi-automatic bottle blowing machine can blow PET carbonated drink bottles, mineral water bottles, cosmetics bottles, hot filled bottles, pesticide bottles, oil bottles, etc.

5.The bottle blowing machine is suitable for PP milk bottle series products, with high transparency, high temperature up to 120 degrees, and can withstand secondary high temperature disinfection. It is a substitute for glass bottles.

6.The power consumption of the whole machine is small and the production capacity is high, which greatly reduces the customer's operating costs and improves the customer's production efficiency.

| ITEM | SH-25 |

| Max.Container volume | 2Cavites-5L |

| Max.stretching stroke | 540mm |

| Number of cavities | 5L-2Cavites |

| Theoretical output | 800-900bph |

| Max.mould thickness | 320mm |

| Voltage standard | 380v/3PH/50Hz |

| Total power(full loaded) | 5-15KW |

| Min.air compressor | 1.6m³/3.0Mpa |

| Machine size | 2.0x0.8x1.7m |

| Heater size | 2.2.x0.6x1.4cm |

| Net weight | 1000Kg |

| Clamping stroke | 210-260mm |

| Neck diameter range | 28-120mm |

| Max.Container diameter | 300mm |

1.DETAILED IMAGES

Shuanghao machine seiko to create quality details

2.Cooperated Brand

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

3.Product Features

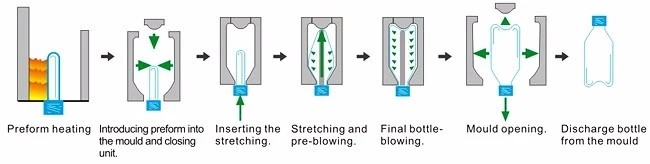

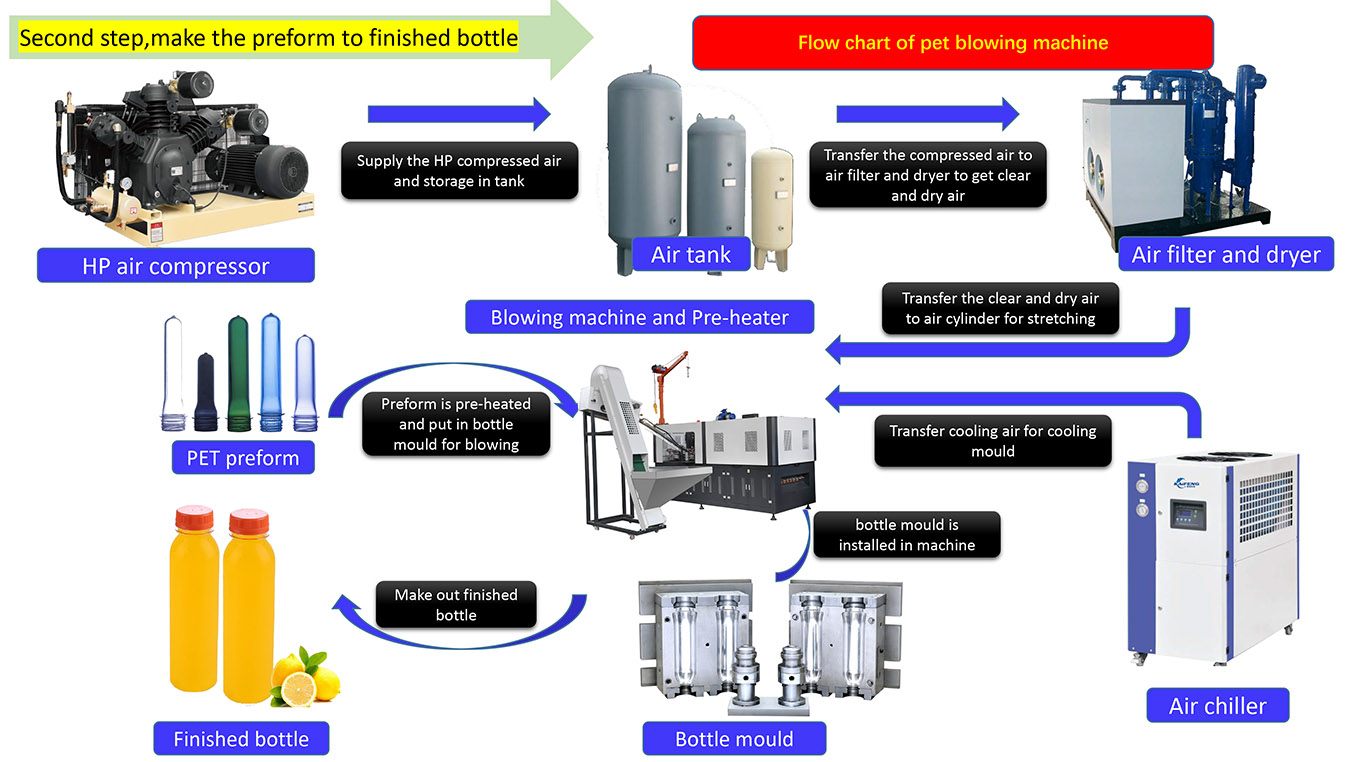

4.Working Process